Mohan Nagar, Ghaziabad, Uttar Pradesh

- GST NO. : 09AAACY1001E1ZX

1 Piece (MOQ)

| Business Type | Manufacturer, Exporter, Supplier |

| Automation Grade | Fully Automatic |

| Brand Name | Steri |

| Material | Stainless Steel |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

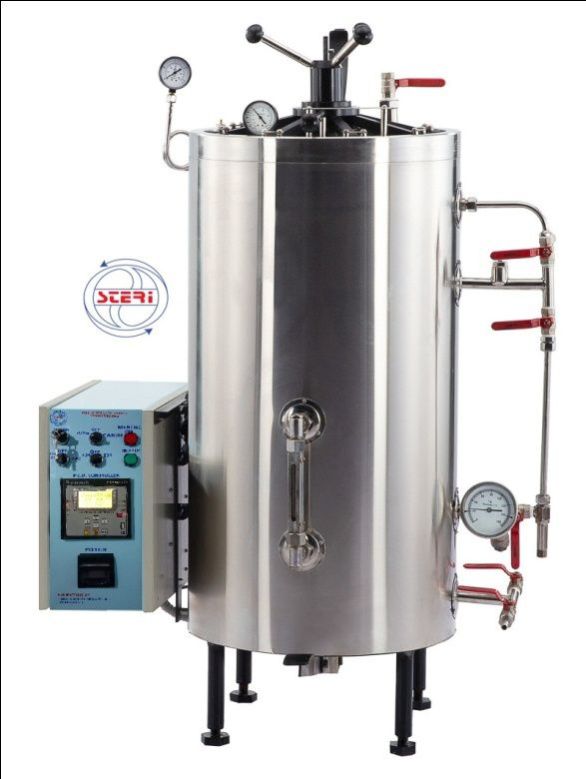

Steri Vertical Steam Sterilizer - Gold Model

Achieve Unmatched Sterilization with Full Automation

- The Steri Vertical Steam Sterilizer Gold Model Sets the Standard for Advanced Sterilization, Offering a Fully Automatic System with Single Cycle Preset Functionality. Engineered for Efficiency and Ease of Use, This Model Combines Precision and Automation, Allowing You to Focus on Other Critical Tasks While the Autoclave Manages the Entire Sterilization Process.

Cutting-Edge Automated Features

- Fully Automatic System: Controlled by a Precision Timer and Highly Advanced Sensors, This System Includes High-Quality Branded Solenoid Valves for Reliable Performance.

Automated Processes:

- Automatic Air Removal (Pulsing): Efficiently Purges Air from the Chamber for Optimal Steam Penetration.

- Automatic Steam Inlet: Seamlessly Channels Steam from the Jacket to the Chamber.

- Time-Based Temperature and Pressure Control: Ensures Precise Control During the Sterilization Phase.

- Automatic Steam Exhaust: Efficiently Releases Steam Post-Sterilization, Reducing Condensation Risks.

- Automatic Drying: Completes the Cycle with Thorough Drying, Ensuring Your Instruments Are Ready for Use.

User-Friendly Operation:

- This Fully Automated System Comes with Comprehensive Digital Displays: Digital Temperature Display, Digital Timer, and Digital Pressure Display for Precise Monitoring and Allowing Users to Perform Other Activities While the Autoclave Manages the Sterilization Process.

Superior Construction and Design

- Triple-Walled Construction: Features a Robust Inner Chamber, Steam Jacket, and Outer Covering, All Crafted from Thick Stainless Steel 304 for Maximum Durability.

- Complete Ss304 Piping: Ensures Superior Corrosion Resistance and Long-Lasting Performance.

- High-Quality Insulation: Utilizes Mineral Glass Wool for Exceptional Heat Retention and Energy Efficiency.

- Advanced Welding: Constructed with Complete Argon Arc Welding for Enhanced Durability and Safety.

Complete Equipment and Safety Features

- Built-In Steam Generator: Efficiently Feeds Steam to the Chamber for Consistent Sterilization Cycles.

- Precision Gauges: Includes Pressure Gauge, Compound Gauge, Temperature Gauge, and a Dial Thermometer for Accurate Control.

- Automatic Pressure Control Switch: Maintains Optimal Pressure Levels Automatically.

- Comprehensive Drainage: Features a Drain Valve and Water Level Indicator Housed in a Sleek Ss Enclosure.

- Hi-Tech Mechanical Vacuum System: Ensures Thorough Sterilization by Removing Air Pockets and Enhancing Steam Penetration.

Unmatched Safety Features

- Energy Efficiency Maximizer: Reduces Power Consumption for Eco-Friendly Operation.

- Low Water Cut-Off System: Protects the Autoclave from Damage by Automatically Shutting Off in Low Water Conditions.

- Isi Mark Heater: Certified Heater Ensures Reliable Performance.

- Multiple Safety Valves: Includes Safety Valves, a Shutoff Valve in the Water Indicator, and a Vacuum Breaker for Enhanced Safety.

- Current Leakage Breaker: Protects Against Electrical Faults, Ensuring User Safety.

- Power Requirements: Designed to Operate on a Three-Phase 440 Volts 50hz Supply, Providing Consistent and Reliable Power.

Process Control and Other Features:

1. STAINLESS STEEL 304 TRIPLE WALLED CONSTRUCTIONS:

- a) Triple walled design with mineral wool insulation for prevention of burn to users.

- b) Top quality stainless steel 304/316 construction including piping to avoid corrosion and contamination of.

2. AUTOMATIC CONTROL SYSTEM:

The Machine is equipped with 5 automatic control function controlled by Pre-programmed 4.2” Coloured Touch Screen Display.

- a) Auto Ster

- b) Auto Exhaust

- c) Auto Vacuum Dry

- d) Auto Air Dry

3. DUAL OPERATION SYSTEM:

- The Machine is capable of running in manual via multi-valve and in automatic mode via Pre-programmed 4.2” Coloured Touch Screen Display.

4. Pre-Progammed Cycles:

The Sterilizer Comes with 4 Pre-Programmed Sterilization Cycles as Mentioned Below:

- A) Instrument Cycle

- B) Fabric Cycle

- C) Liquid Cycle

- D) Customer Variable Cycle

The Machine Having User Variable Cycle Will Allow User to Customize the Temperature Settings, Pressure Settings and Vacuum Pulse Settings.

5. USER CUSTOMIZABLE CYCLE:

- The machine having user variable cycle will allow user to customize the temperature settings, pressure settings and vacuum pulse settings.

6. PRINTING FACILITY:

- a) The user is record the progress of the sterilization cycle in real time therefore online real time printing facility will be provided.

- b) The user can print the following details:

Date and time of the cycle.

Status of the cycle.

Temperature at drain and chamber pressure at every event change and during sterile hold are printed.

Optional:- Thermal Printer will be provided at extra cost with this model.

7. QUICK HOT AIR DRYING SYSTEM:

- Specially designed drying valves have been provided to ensure each load comes out completely dry.

8. State of the Art – Vacuum System:

- Vacuum Is a Must for Optimum Steam Penetration & Drying of Sterilization Load. Our “Steri“ Vertical Steam Sterilizer Is Equipped with Cutting Edge Vacuum Which Sets Us Apart from Our Competition.

- Optional:- Vacuum Pump Available at Extra Cost.

9. Automatic Low Water Cut Off System:

- The Machine Is Equipped with Automatic Low Water Cut-Off System. When the Water Level Decreases Below a Threshold Then Heating Elements Will Automatically Turn Off. the User Will Be Notified in Case the Water Level Is Not Optimum for Regular Machine Operation.

10. Automatic Pressure Control System:

- The Sterilizer Has Automatic Pressure Control Switch Which Automatically Maintain the Desired Pressure and Restricts Any Abnormal/ Unsafe Rise of Pressure in the Sterilizer.

- Abnormal/ Unsafe Rise of Pressure in the Sterilizer.

11. Extra Port for Calibration & Validation:

- The Sterilizer Is Equipped with External Port for the Sterilizer Calibration & Validation.

12. Water Level Indicator:

- The Sterilizer Is Equipped with Water Level Gauge Glass to Indicate the Water Level.

13. Airtight Sealing:

- Heavy Duty Branded Silicon Gasket Will Be Provided for Airtight Seal.

14. Electric Solenoid Valve:

- The Sterilizer Is Equipped with Branded Electric Solenoid Valves for Automatic Process.

15. Analogue Gauges:

- A) The Sterilizer Is Fitted with Branded Nabh Calibrated Analogue Chamber Pressure (Compound) Gauge to Measure the Pressure and Vacuum of Chamber.

- B) The Sterilizer Is Fitted with Branded Nabh Calibrated Analogue Jacket Pressure Gauge to Measure the Jacket & Boiler Pressure.

- C) The Sterilizer Is Fitted with Branded Nabh Calibrated Analogue Chamber Temperature Gauge to Measure and Indicate Temperature.

16. Safety Features:

16.1 Automatic Shut Off Valve:

- Prevents Hazardous Leakage of Hot Steam and Boiled Water Due to Breakage of Glass Tube.

16.2 Hydraulic Testing:

- Complete Sterilizer Including Chamber, Jacket, and Piping Are Hydraulically Tested at 2 Times the Working Pressure.

16.3 Vacuum Breaker:

- The Sterilizer Is Fitted with Vacuum Breaker System to Prevent Collapsing of Jacket Due to Vacuum Formed by Condensation of Steam.

16.4 Safety Valve:

- The Sterilizer Is Fitted with Spring Loaded Dual Safety Valves.

16.5 Insulation:

- The Sterilizer Is Completely Insulated to Prevent Any Burns Caused Due to Accidental Contact to Sterilizer Body.

Looking for "YSU-404 Gold Vertical Cylindrical High Pressure Steam Sterilizer" ?

Explore More Products