Mohan Nagar, Ghaziabad, Uttar Pradesh

- GST NO. : 09AAACY1001E1ZX

1 Piece (MOQ)

| Business Type | Manufacturer, Exporter, Supplier |

| Automation Grade | Fully Automatic |

| Brand Name | Steri |

| Material | Stainless Steel |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

Process Control and Other Features:

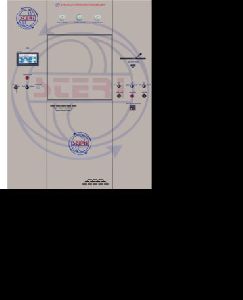

1. AUTOMATIC CONTROL SYSTEM:

The Machine is equipped with 5 automatic control function controlled by Pre-programmed 4.2” Coloured Touch Screen Display.

a) Auto Ster

b) Auto Exhaust

c) Auto Vacuum Dry

d) Auto Air Dry

e) Auto Water Feeding

2. PRE-PROGAMMED CYCLES:

The sterilizer comes with 4 pre-programmed sterilization cycles as mentioned below:

a) Instrument Cycle

b) Fabric Cycle

c) Liquid Cycle

d) Customer Variable Cycle

The machine having user variable cycle will allow user to customize the temperature settings, pressure settings and vacuum pulse settings.

3. AUTOMATIC WATER FEEDING SYSTEM:

The Sterilizer has automatic water feeding system ensuring autoclave to run without any interruption.

4. PRINTING FACILITY:

a) The user is record the progress of the sterilization cycle in real time therefore online real time printing facility will be provided.

b) The user can print the following details:

Date and time of the cycle.

Status of the cycle.

Temperature at drain and chamber pressure at every event change and during sterile hold are printed.

5. STATE OF THE ART – VACUUM SYSTEM:-

a) Venture vacuum device is provided to create high vacuum pressure leading to dry loads on completion of sterilization.

b) The Sterilizer has quick dry ejector for create high vacuum.

Note:- Vacuum pump available at an extra cost.

6. SAFETY FEATURES:

6.1 HYDRAULICALY TESTED:

Complete sterilizer including chamber, jacket, and piping are hydraulically tested at 2 times the working pressure.

6.2 AUTOMATIC PRESSURE CONTROL SYSTEM:

The sterilizer has automatic pressure control switch which automatically maintain the desired pressure and restricts any abnormal/ unsafe rise of pressure in the sterilizer.

6.3 AUTOMATIC SHUT OFF VALVE:

Prevents hazardous leakage of hot steam and boiled water due to breakage of glass tube.

6.4 AUTOMATIC VACUUM BREAKER:

The sterilizer is fitted with vacuum breaker system to prevent collapsing of jacket due to vacuum formed by condensation of steam.

6.5 AUTOMATIC LOW WATER CUT OFF SYSTEM:

The machine is equipped with automatic low water cut-off system. When the water level decreases below a threshold then heating elements will automatically turn off. The user will be notified in case the water level is not optimum for regular machine operation.

6.6 AUTOMATIC MECHANICAL DOOR LOCKING SYSTEM:

The sterilizer is equipped with automatic mechanical door locking system which prevents the user to open the door until the atmospheric pressure is achieved inside the chamber.

6.7 DUAL SAFETY VALVE:

The sterilizer is fitted with spring loaded dual safety valves.

6.8 HEAT PROTECTION:

The sterilizer is completely insulated with chloride face mineral glass wood to prevent any burns caused due to accidental contact to sterilizer body.

6.9 STEAM LEAKAGE PROTECTION:

Heavy Duty branded silicon gasket is provided for airtight seal to prevent any leakage of steam.

6.10 NABH CALIBRATED GAUGES:

All our gauges including pressure, compound and temperature are calibrated & certified by Indian most trusted NABH lab certified.

7. SEPARATE STEAM GENERATOR:

The sterilizer has separate steam generator with manual water feed control valve, separate manual valve for water drain and water level indicator.

8. WATER LEVEL INDICATOR:

The sterilizer is fitted with water level gauge glass to indicate the water level.

9. VALIDATION PORT:

The sterilizer is equipped with external validation port for the sterilizer calibration.

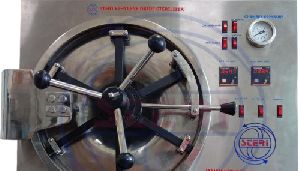

Looking for "YSU-608 Silver Fully Automatic Horizontal High Pressure Steam Sterilizer" ?

Explore More Products